At InGenius, we’re passionate about materials that enable better products and processes.

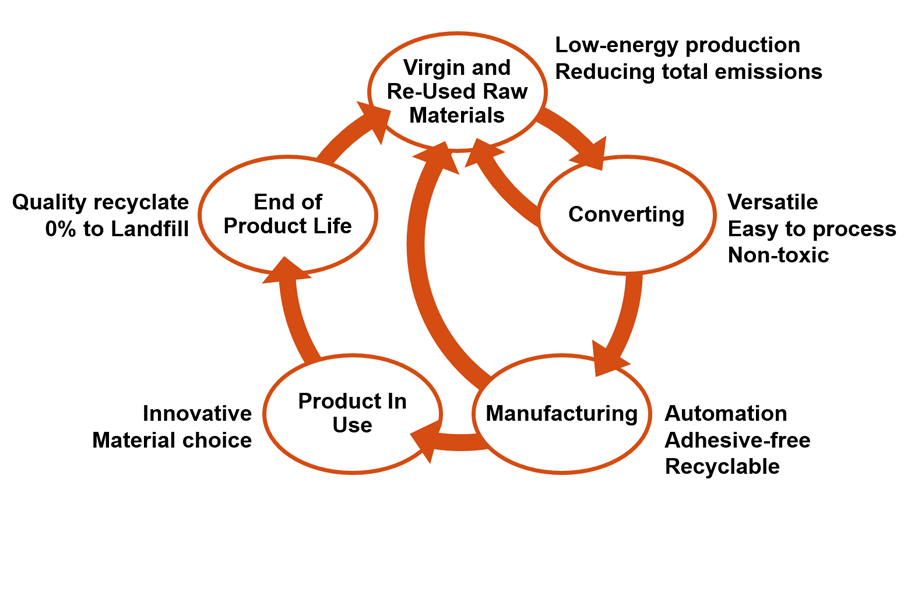

In our current initiatives, we’re focusing on using polyolefin polymers to enable closed-loop systems, here’s why:

Used properly, combinations of ethylene and propylene help us to conserve the hydrocarbon raw materials, maximising the useful life of the polymer through reuse and recycling, reducing waste to landfill.

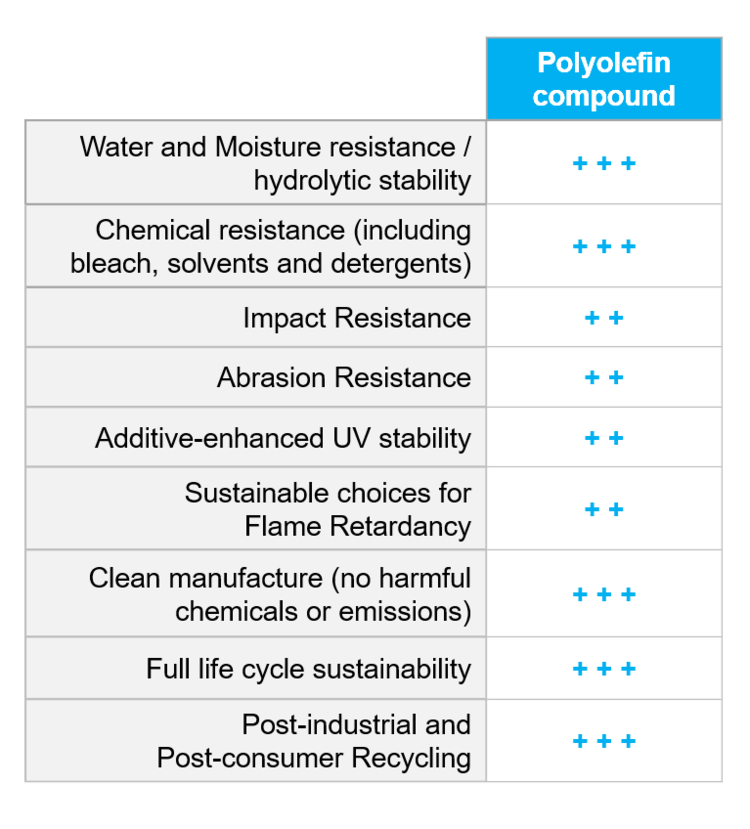

In comparison to other polymers, polyolefins have more value in closed-loop systems due to their better resistance to heat cycles, versatility in conversion processes and performance-in-use characteristics.

In production, polyolefins use less water, produce less CO2, require less energy and have lower toxicity than most other polymers in cradle-to-cradle life-cycle analysis.

Technical developments made possible with polyolefins can deliver more sustainable solutions, doing more things for more people around the world.

Example: New Innovations in 3D Printing

Through our sister company In Form Design, InGenius has been involved in the launch of a range of polyolefin 3D printing filaments (Forefront Filament) so that designers, product manufacturers and polymer companies can more easily envisage what’s possible with polyolefins. They can allow companies to test the market for their products with small batch manufactured commercial products before moving into mass production technologies such as injection moulding.

Is InGenius Only About Polyolefins?

Not at all – whatever the product or packaging challenge, InGenius can help to make the right material choices. InGenius analyses the mix of Functional, Economic, Emotive and Environmental performance that is needed to meet particular human needs and preferences.